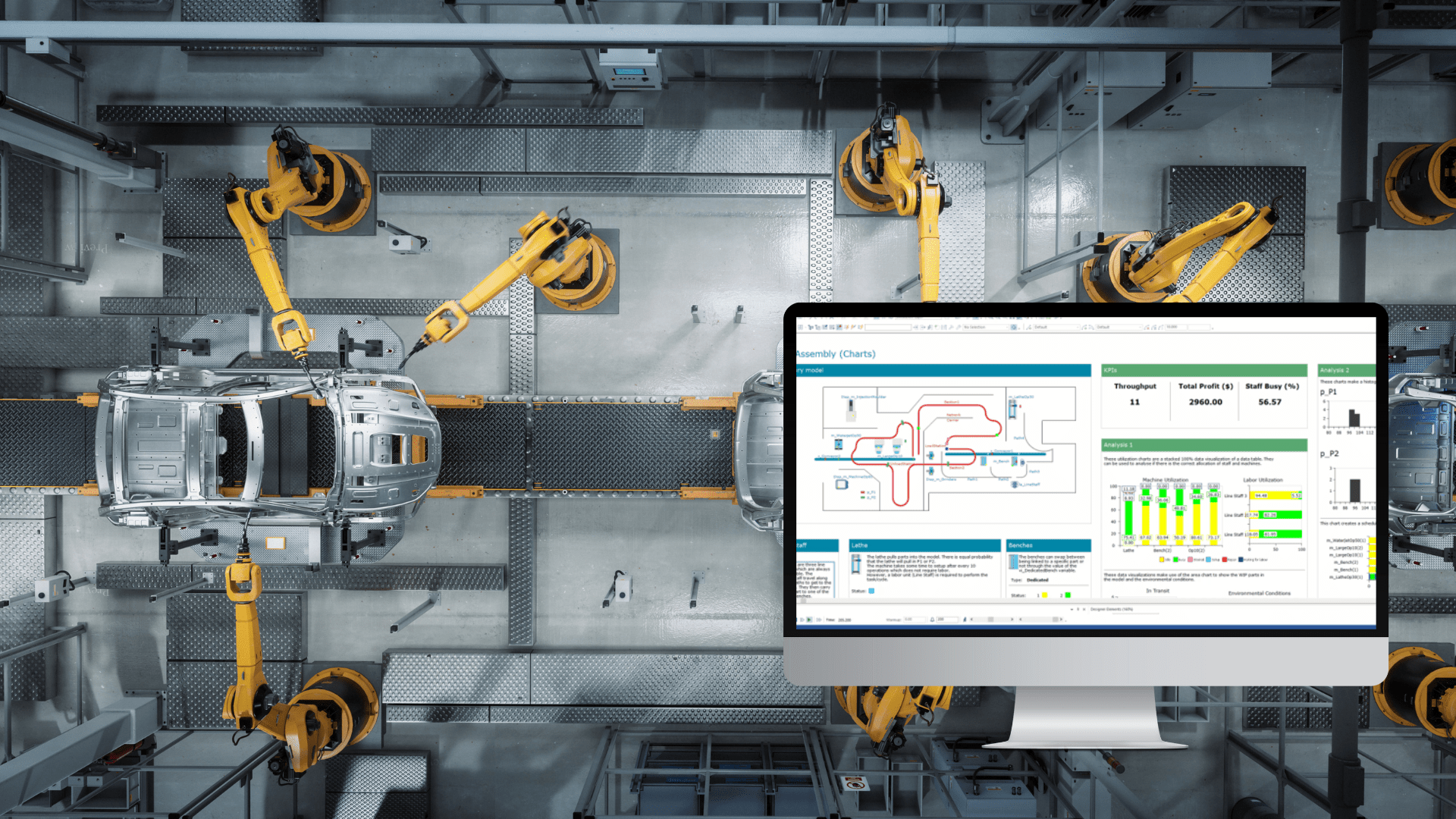

Predictive Simulation Suite

Predictive simulation software helps to build dynamic models of processes and operations to improve productivity and maximise profitability.

Contact usContact us

Predictive simulation is the science of creating accurate models to represent the behavior of real-life processes.

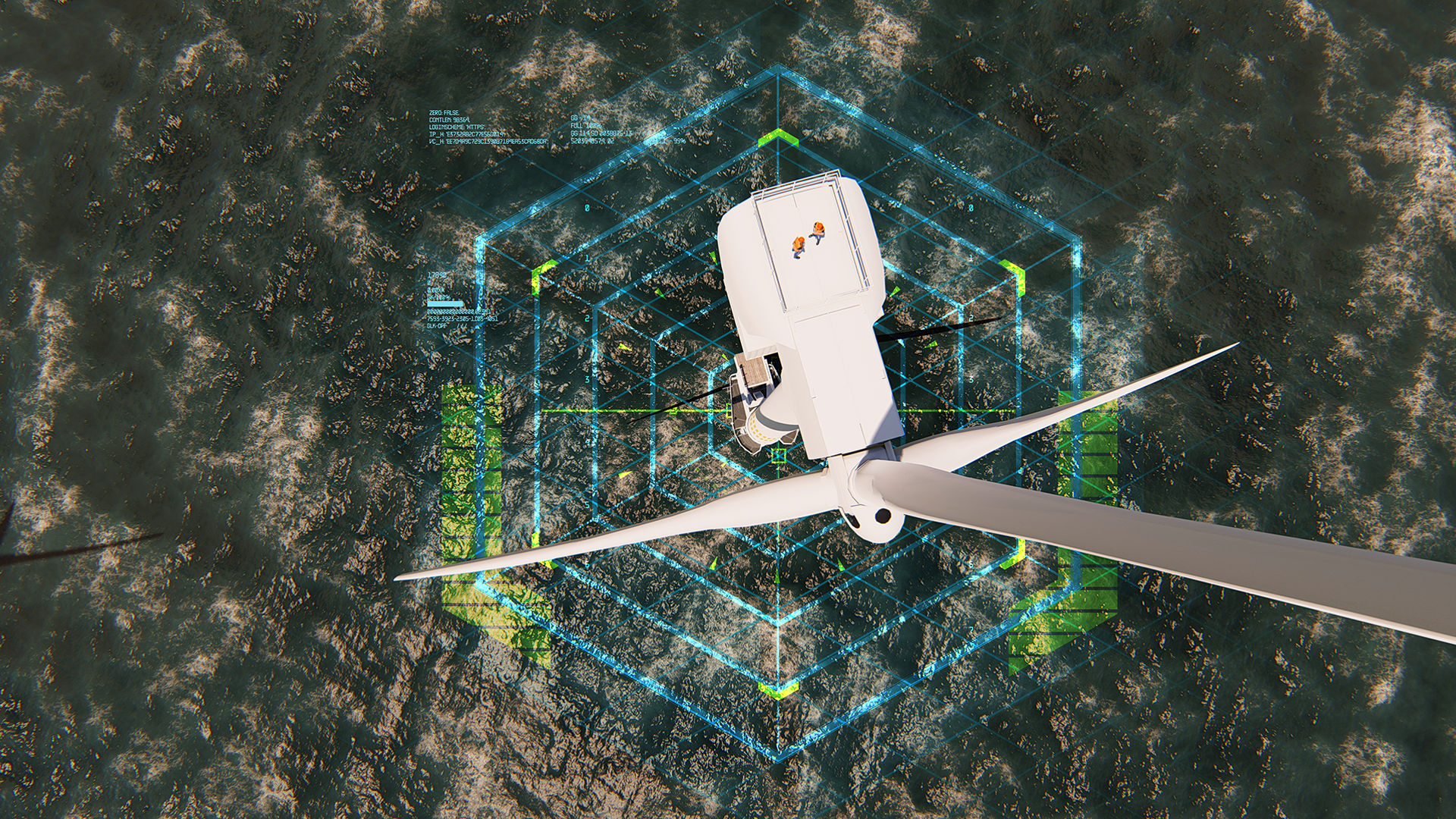

Today’s businesses are facing increasingly difficult and complex decisions. Markets are changing constantly, competition is fierce, and customers are demanding innovative new experiences and consistently high service levels. Predictive simulation simplifies this complexity. A simulated model of your business generates powerful future-state data and helps demystify much of the analytical process by providing a rich interactive visualisation of information. Predictive simulation helps both analysts and decision-makers understand their business processes, data and how they affect one another across diverse sectors such as manufacturing, LNG, supply chain, logistics and more.

Why predictive simulation?

Evidence-based decision making

Analyse ideas and 'what-if' scenarios where testing in real life would be impractical, expensive and dangerous

Operational safety and efficiency

Secure stakeholder buy-in

Communicate challenges and opportunities more clearly, accelerating stakeholders and investor buy-in

Maximise return on investment

Understand the impact of change to help optimise resources and drive higher return on investment

Our predictive simulation products

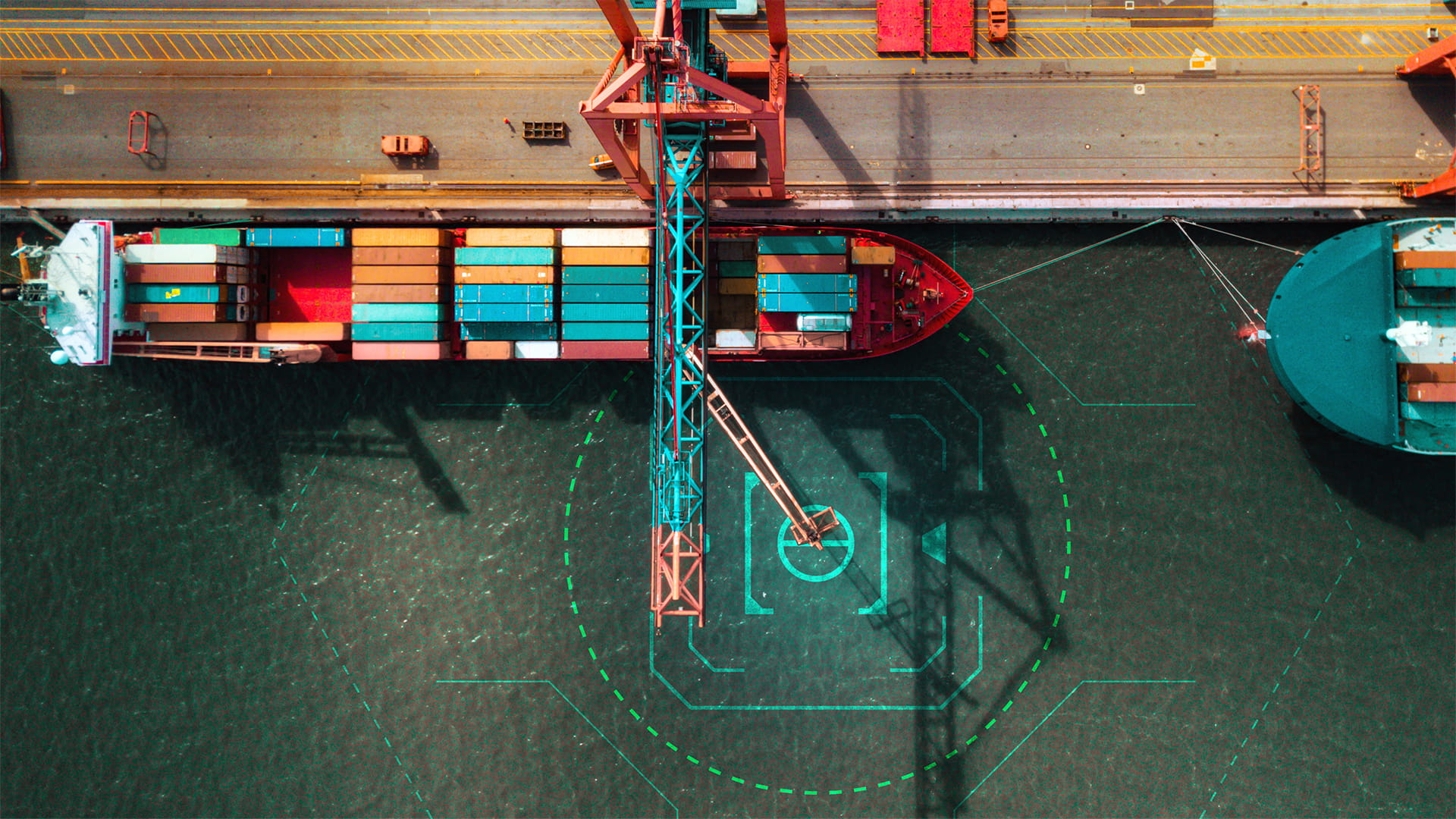

Mastering your supply chain & logistics

Future-proof, resilient solutions

Are your supply chain and logistics fit for changing demand patterns, disruptive events and resource scarcity?

Predictive simulation supports supply chain planning by harnessing complexity and managing variability. Using predictive simulation, along with a mix of process experience, data science expertise, digital tools and technology, our supply chain experts can provide support from strategy and planning through to implementation.

How can predictive simulation help future-proof your operations?

Thanks to the modelling, we’ve been able to implement steady improvements in our processes, and simulation has become a key part of Nissan’s adoption of Industrial IoT and smart technology.