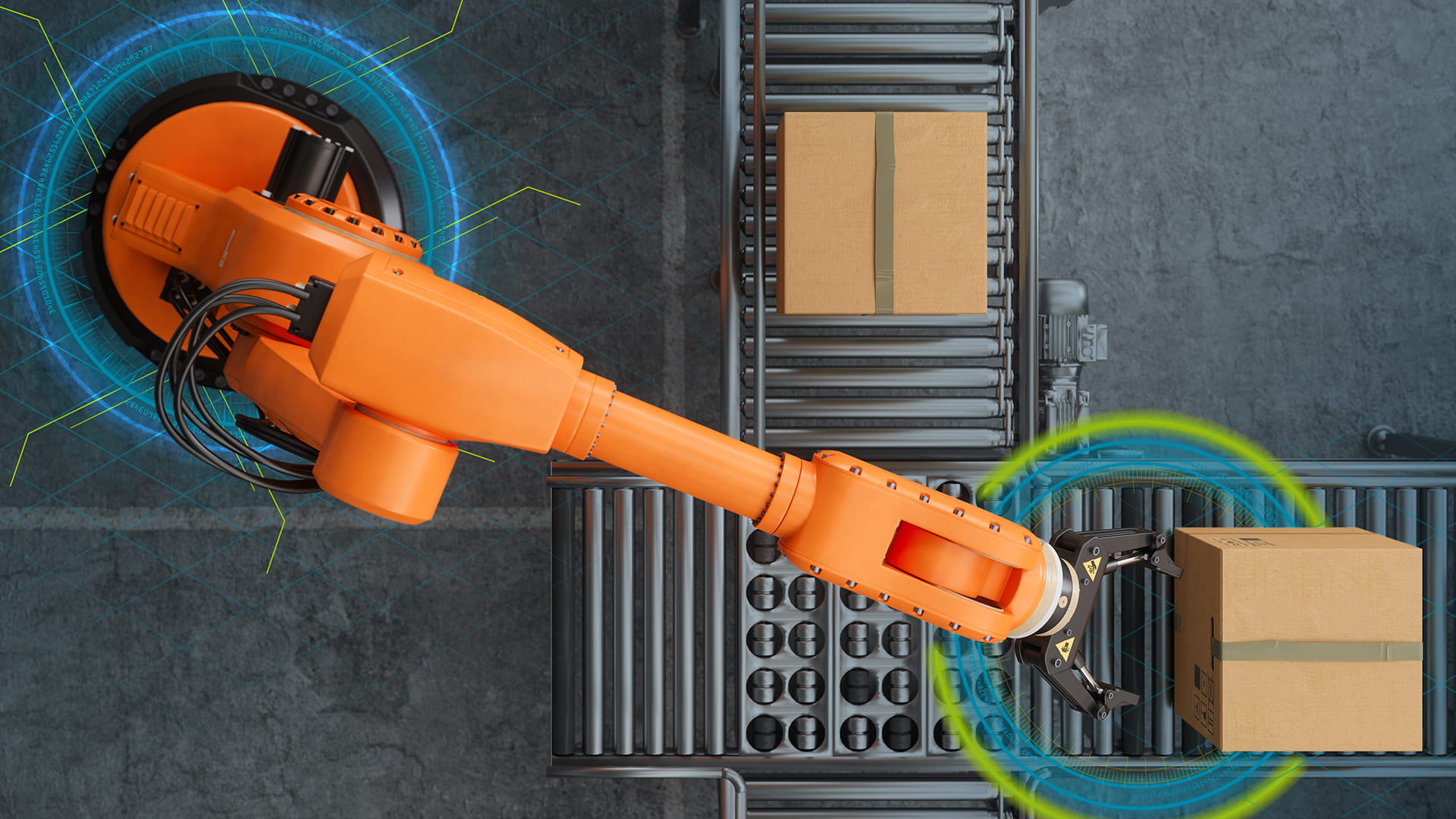

Industry & supply chain optimisation

Are you looking at ways to increase production capacity, boost throughput or cut costs? Or expanding a facility, installing a new line or introducing automation? Use Twinn to understand trade-offs, create evidence-based business cases and de-risk decision-making.

No matter what industry, Twinn helps answer the significant value-generating questions around opex performance, capex rightsizing and KPI optimisation.

Twinn solutions are implemented in industries like automotive, aerospace, food & beverage (FMCG) and general manufacturing companies. We’re talking about questions key to Industry 4.0 ambitions like: “How are my assets performing right now?” and “When should we invest in new lines/automation?” And we’re talking about key continuity questions like: “What process performance can I expect in the next 24 hours?” and “How do we future-proof our supply chain to ensure competitive advantage 3 to 5 years from now?”

With our digital twin and decision support solutions, you get end-to-end visibility and control through real-time “describe, monitor and alert” insights. Using our predictive simulation expertise, you can gamify “what-if” decision-making by testing and comparing alternative ideas and optimising future state performance.

The result: de-risked decision-making.

What you can do with Twinn

Understand

The current state of performance, operations and supply chains in real-time using digital twins

- Access all asset data, models and documentation in a central, cloud-based platform so you can monitor performance, guide training, plan maintenance and manage projects more efficiently

- Get an end-to-end view of complex operational processes across production and supply chains

Predict

Anticipate problems arising from maintenance, supply chain disruption, operational bottlenecks and more

- Test new designs, processes and facilities in a risk-free digital environment so you can see their impact before you spend any budget

- Validate business cases for technology investments by using simulation to provide evidence on what will deliver the greatest return on investment

Prevent

Unnecessary delays, costs and risks

- Monitoring and alerting help you take a holistic and informed approach to predictive maintenance, so you minimise the impact on operations and customers

- Use Twinn simulation software tools to model “what-if” scenarios, helping you mitigate against unintended consequences that could cause new bottlenecks or costs

Optimise

Your approach to customer centricity, sustainability, and digital transformation

- Gain the insight needed to answer complex optimisation questions like: Where should we store stock? How should you size and sequence batches? How can we reduce energy consumption? How can we improve scheduling and resource allocation?

- Boost agility and resilience by using digital twins to optimise your supply chain strategy, production processes and digital transformation roadmap