Business resilience planning: How to plan for uncertainty and react with confidence

“How do we need to set up and operate over the next 12 to 18 months to ensure the business is resilient, whatever volatility and uncertainty come our way?”

This is the key question facing business leaders, supply chain managers and plant managers. Because resilience is mission-critical when you have aggressive performance targets against the backdrop of inflation, rising energy prices, labour market constraints and logistics disruptions.

To hit those targets, business problem owners need to be confident their operations and processes are robust and sufficiently insulated against volatility outside their direct control. Predictive digital twins, powered by business process simulation technology, are an increasingly utilised tool for providing that confidence – helping you thrive (and not just survive) in an uncertain landscape.

Let's explore why.

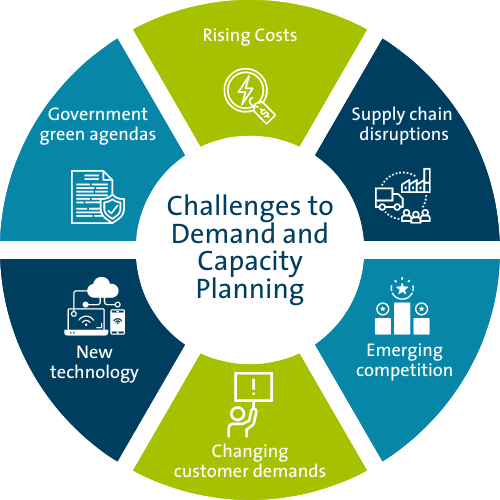

Demand and capacity planning are more complex than ever

In times of economic and business stability, planning isn’t as challenging. You can make reasonable forecasts about demands and can implement systems that enable you to respond. However, in this uncertain economic and geopolitical environment, businesses need to account for:

- Macroeconomic uncertainty, global inflation and rising energy prices

- Logistics disruptions and resulting supply chain availability/volatility affected by factors such as the pandemic, Brexit and the war in Ukraine

- Ongoing government green agendas

- Rapidly changing customer demand

- Technology-driven business disruptors

- Emerging competition

In this context, there are so many variables and complex correlations to consider – and the path to success is harder to navigate. It can feel like a minefield to evaluate these challenges and understand how potentially radically different scenarios affect the company’s ability to deliver to plan.

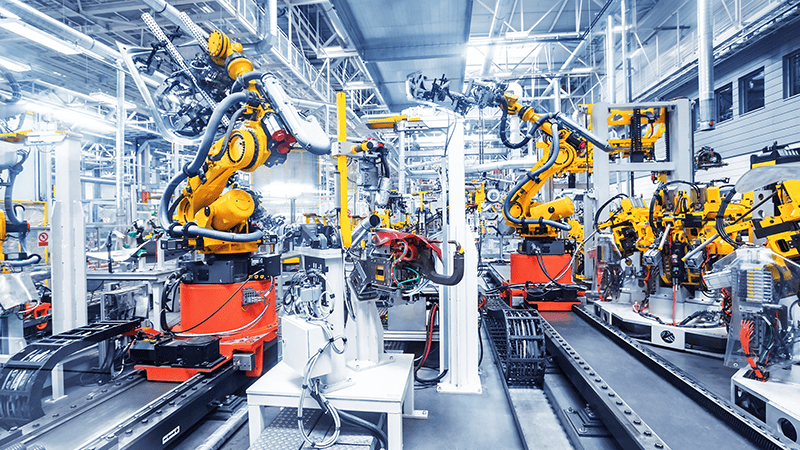

So what’s out there for people looking to make critical decisions around future business footprint; re-shoring; recruitment and skills requirements; automation, innovation and technology investments; or new supply chain configurations?

That’s where predictive digital twins come in.

Predictive digital twins help you cut through complexity and plan effectively

Gartner defines a digital twin as “a digital representation of a real-world entity or system. The implementation of a digital twin is an encapsulated software object or model that mirrors a unique physical object, process, organisation, person or other abstraction.”

Predictive digital twins make sense of complexities. They provide a virtual business to help you answer strategic and tactical questions that affect the organisation’s ability to hit its KPIs. With a digital model of your business, you can ask ‘what-if’ questions, such as:

- Will investment in Industry 4.0 technologies help us improve our responsiveness?

- What are the risks in consolidating production into a smaller footprint?

- Can we successfully move from having a single NDC to having regional ones?

- Should we increase stocks of raw materials or finished goods to mitigate the risk of supply chain disruption?

An individual engineer, analyst or manager can’t answer these questions using a simple spreadsheet or ‘current state’ BI dashboard. These questions involve a myriad of dynamic variables, complex processes, multiple disruptions and near-infinite potential interventions or resulting actions. In other words, they need the capabilities you get with predictive digital twins.

Predictive digital twins let you test your assumptions and avoid costly consequences

We’re seeing lots of businesses draw up best-, medium- and worst-case scenarios as part of their resilience planning. But that approach only works if assumptions are correct.

By applying ‘what if?’ scenarios to dynamic predictive digital twin models of your processes, you can stress test resilience against multiple internal and external variables. Therefore, you’re not working based on assumptions, you’re working with invaluable foresight based on comprehensive, KPI-based analytics.

Using a predictive digital twin significantly mitigates the risks associated with making critical decisions. It gives business problem owners confidence they’re using trusted, informed facts about the likely outcome of a given course of action.

Predictive digital twins are as close to a crystal ball as you can get

With a predictive digital twin of your processes, you can run any scenario and pre-test the business’ ability to respond to variability, volatility and uncertainty. As a result, you engineer out the risk associated with important operational and strategic ‘what-if?’ questions. That way, you can identify how resilient your business would actually be under any potential future condition.In short, predictive digital twins arm you with both foresights and actionable insights required to make confident and future-proofed decisions that address the resilience risks facing the business.

Want to know more about how predictive digital twins can enhance your resilience planning? Get in touch now.

Do you want to know more or have a question?

Contact our experts!